Solid Oak Desk

This project began as a personal passion. For years, I worked at a table that never quite met my needs and made long hours of study and design work uncomfortable. Over time, through several smaller woodworking and carpentry projects, I developed the skills and confidence to take on something more ambitious — designing and building a custom timber desk entirely from scratch. The goal was to create a workspace tailored to my exact requirements for ergonomics, durability, and aesthetics, blending engineering precision with craftsmanship to produce a piece that was both functional and personal.

The concept generation phase began with hand sketches and ergonomic analysis to identify optimal desk height, leg geometry, and usable workspace. Several layout concepts were explored, balancing stability, comfort, and design appeal. Parametric models were developed in Autodesk Fusion 360, allowing fine adjustments to dimensions and proportions. FEA simulations in Fusion 360 and ANSYS were used to analyse stress distribution and stiffness across various support configurations. The final concept incorporated cross-braced leg structures and metal L-bracket reinforcements to achieve maximum rigidity while maintaining a minimalist aesthetic.

During fabrication, the desk was constructed from 100 × 75 × 5000 mm timber beams, carefully cut to size using a circular saw. Surfaces were refined with a power sander to achieve smooth finishes and precise joint alignment. Assembly employed a combination of wood screws, dowel joints, and metal fasteners, selected for structural strength and long-term durability. Attention was given to joint tolerance, alignment, and surface protection to ensure a professional finish. The completed desk combines analytical design methods with hands-on craftsmanship, resulting in a durable, ergonomic, and visually balanced workspace built for long-term daily use.

Concept Phase

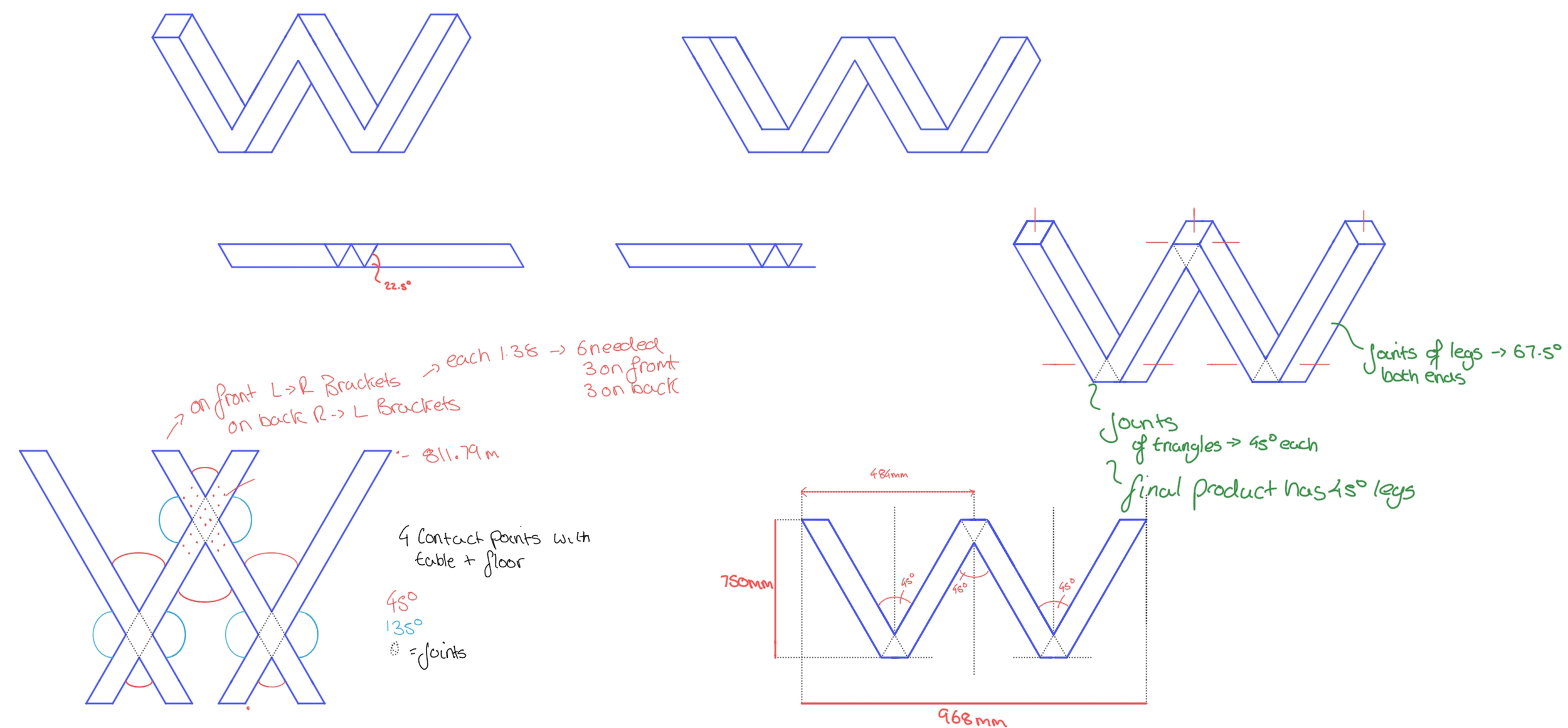

The concept phase began with a clear objective — to design a workspace that balanced comfort, function, and structural integrity while reflecting a minimalist aesthetic. Before modelling or fabrication, I focused on understanding how design decisions would affect usability and long-term comfort. Through sketching, ergonomic analysis, and dimensional planning, I explored multiple desk configurations to optimise leg spacing, surface area, and working height.

CAD Models

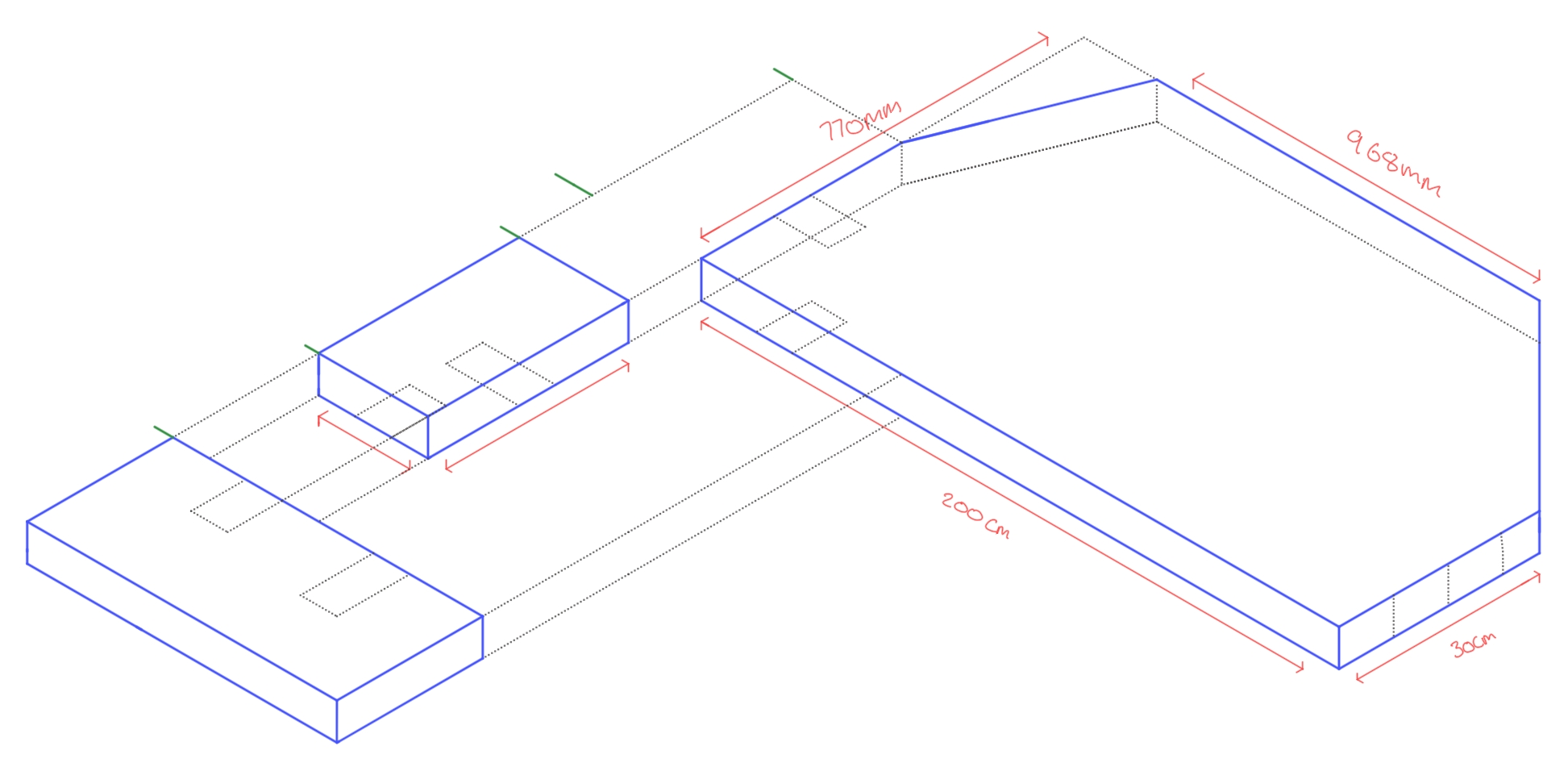

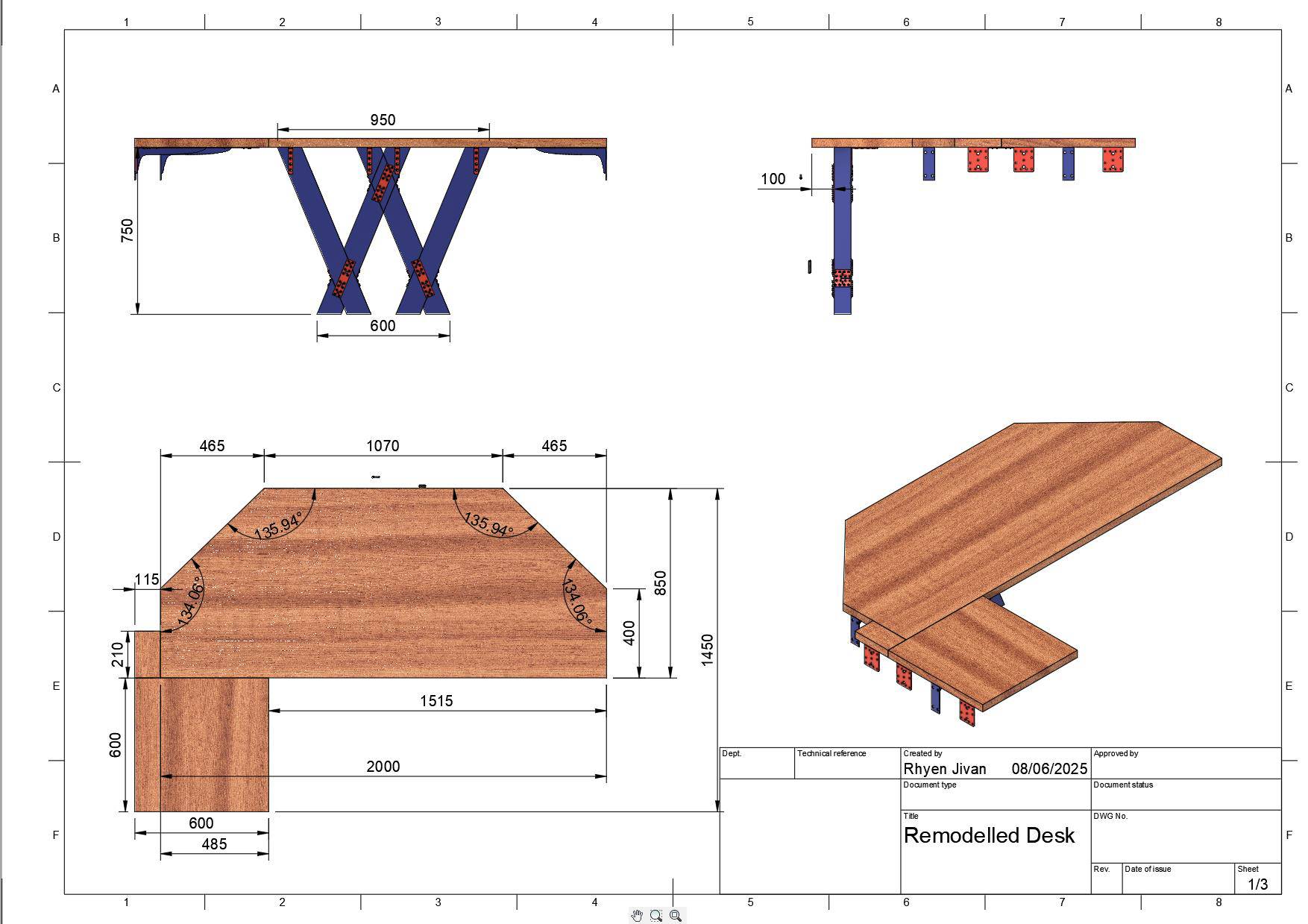

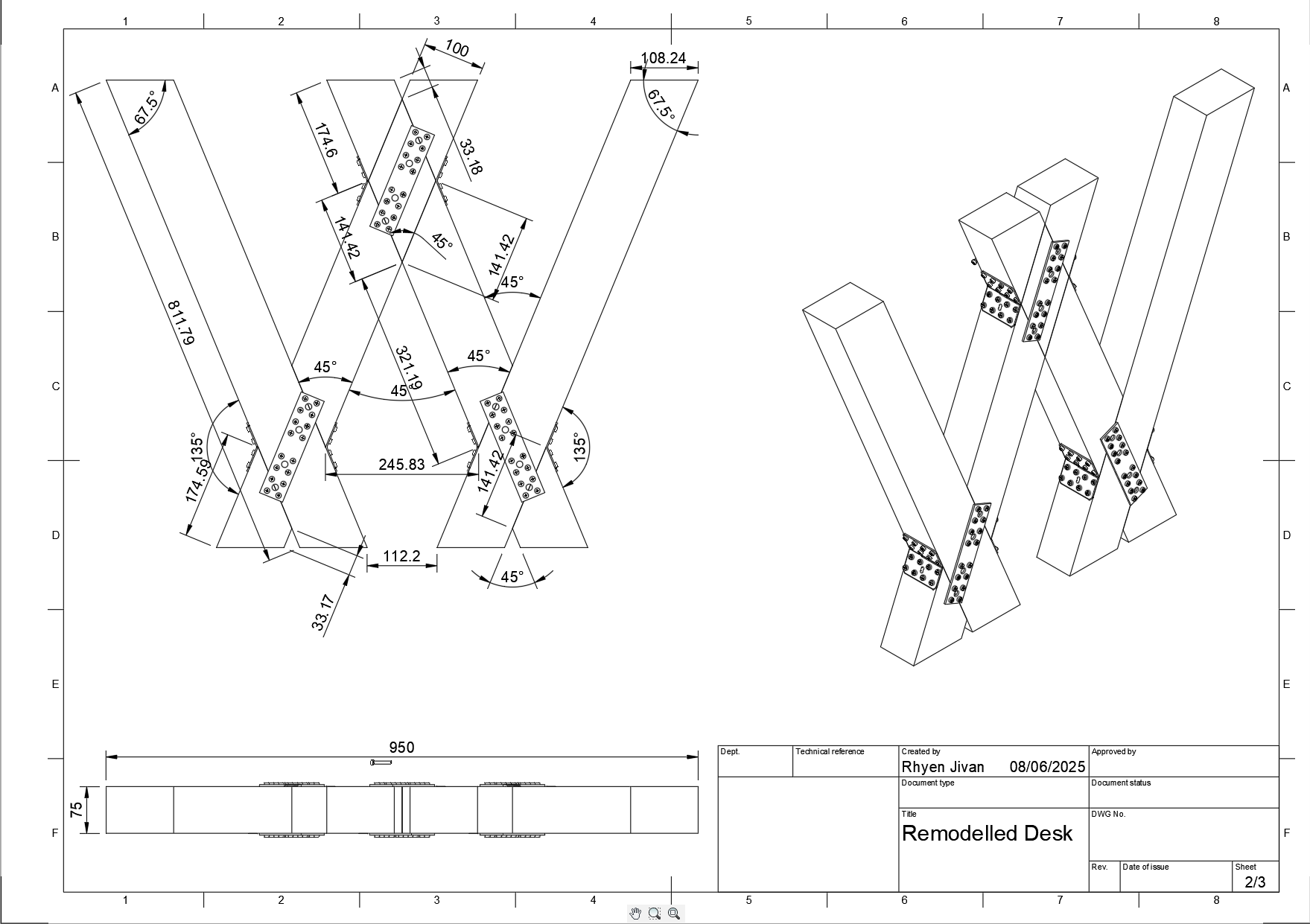

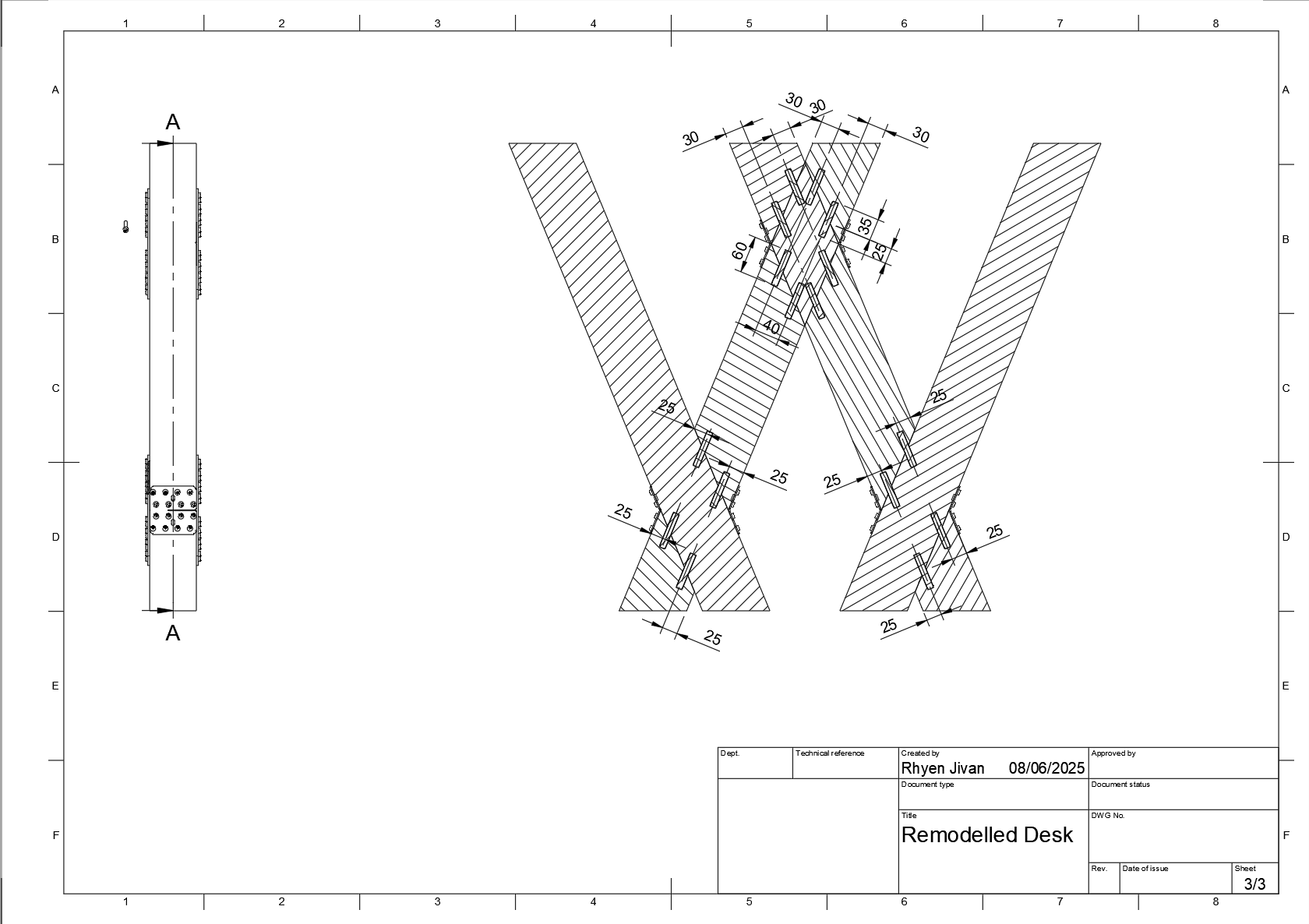

Following the concept development stage, the refined design was brought into Autodesk Fusion 360 for detailed digital modelling. Using parametric modelling techniques, each component of the desk — from the frame to the leg bracing and top surface — was defined with adjustable parameters, allowing efficient refinement of dimensions and proportions throughout the design process.

The CAD environment enabled precise control over alignment, material thickness, and connection geometry while maintaining the flexibility to explore design variations quickly. This stage also allowed the integration of engineering analysis tools, setting the foundation for later FEA simulations to evaluate structural rigidity and load distribution. The final CAD model served as a foundation for producing detailed technical drawings that defined each component’s dimensions, tolerances, and assembly relationships. The CAD drawings here reflect the final design after simulation had been conducted, given that the drawings were to be used as an instruction manual during the manufacturing phase.

Simulations

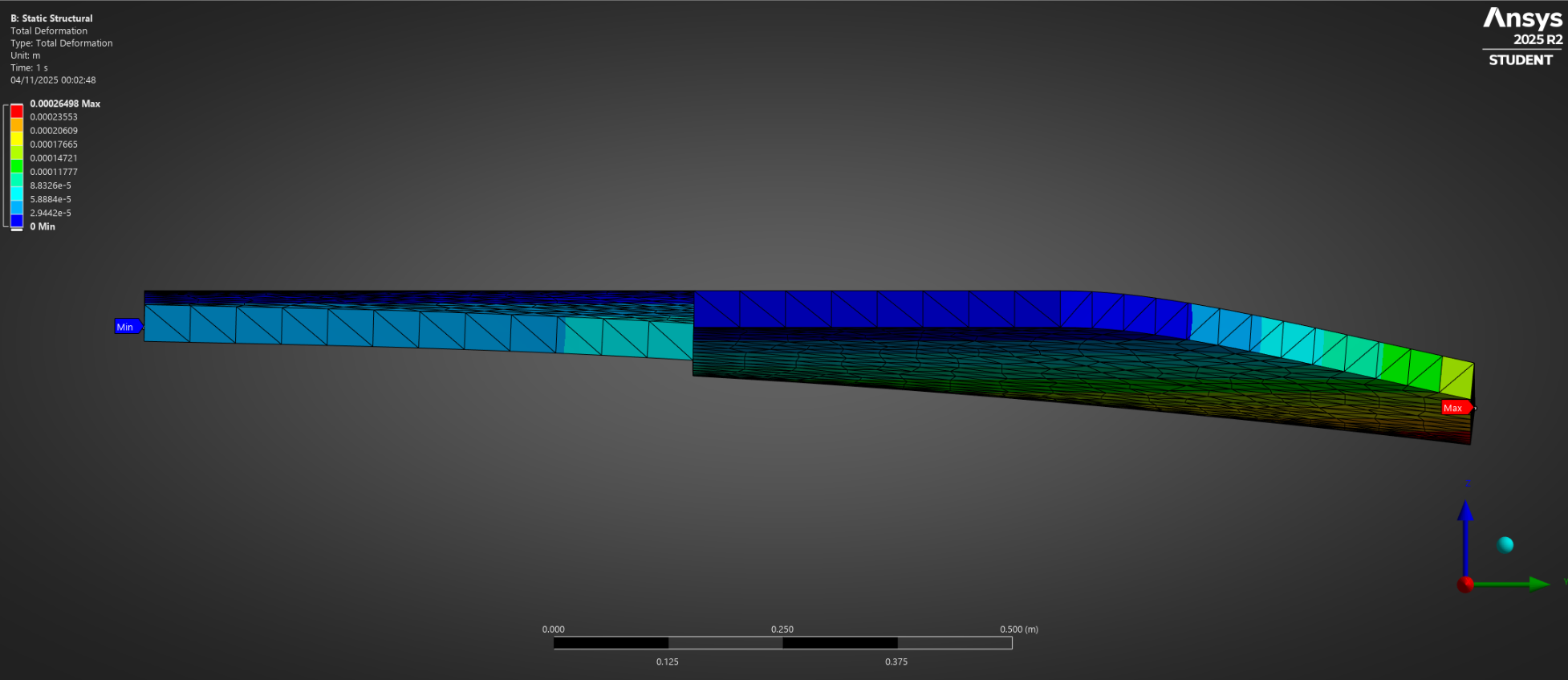

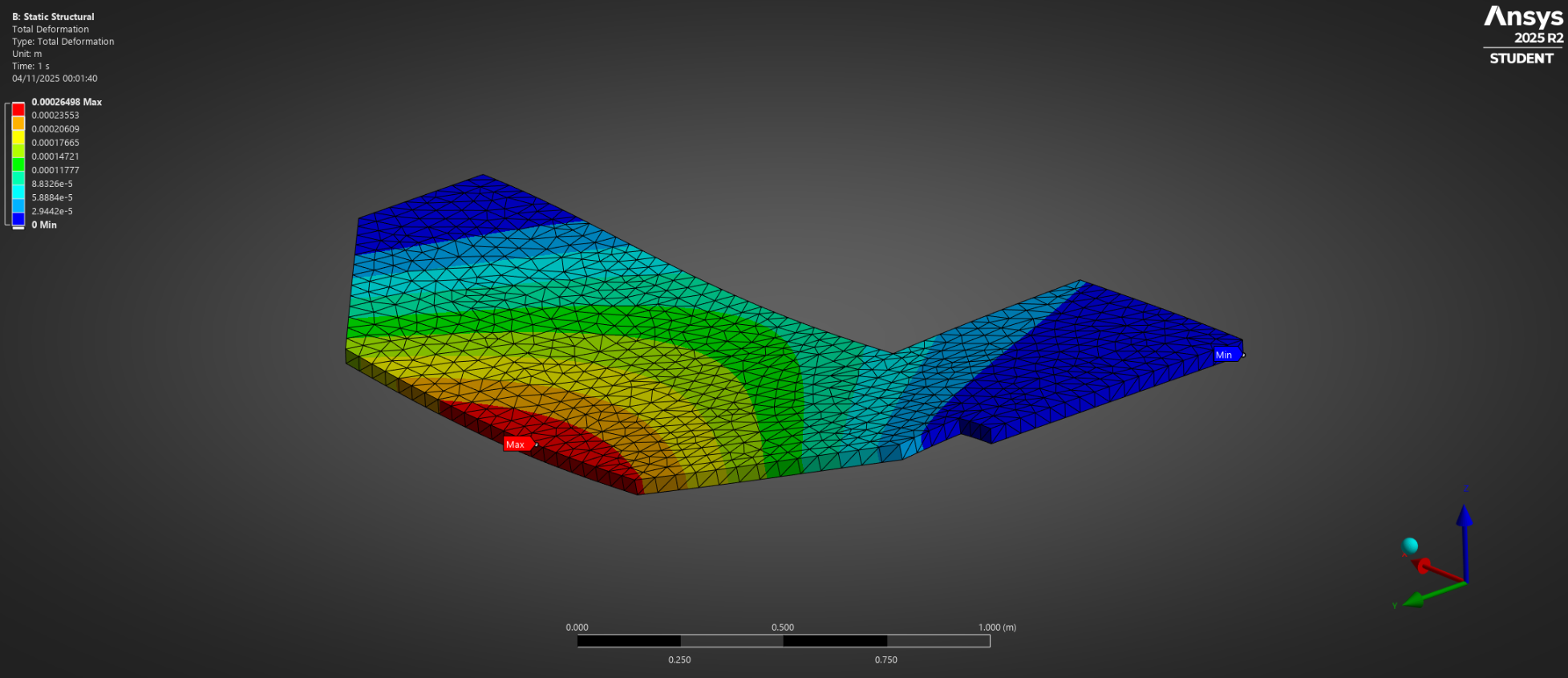

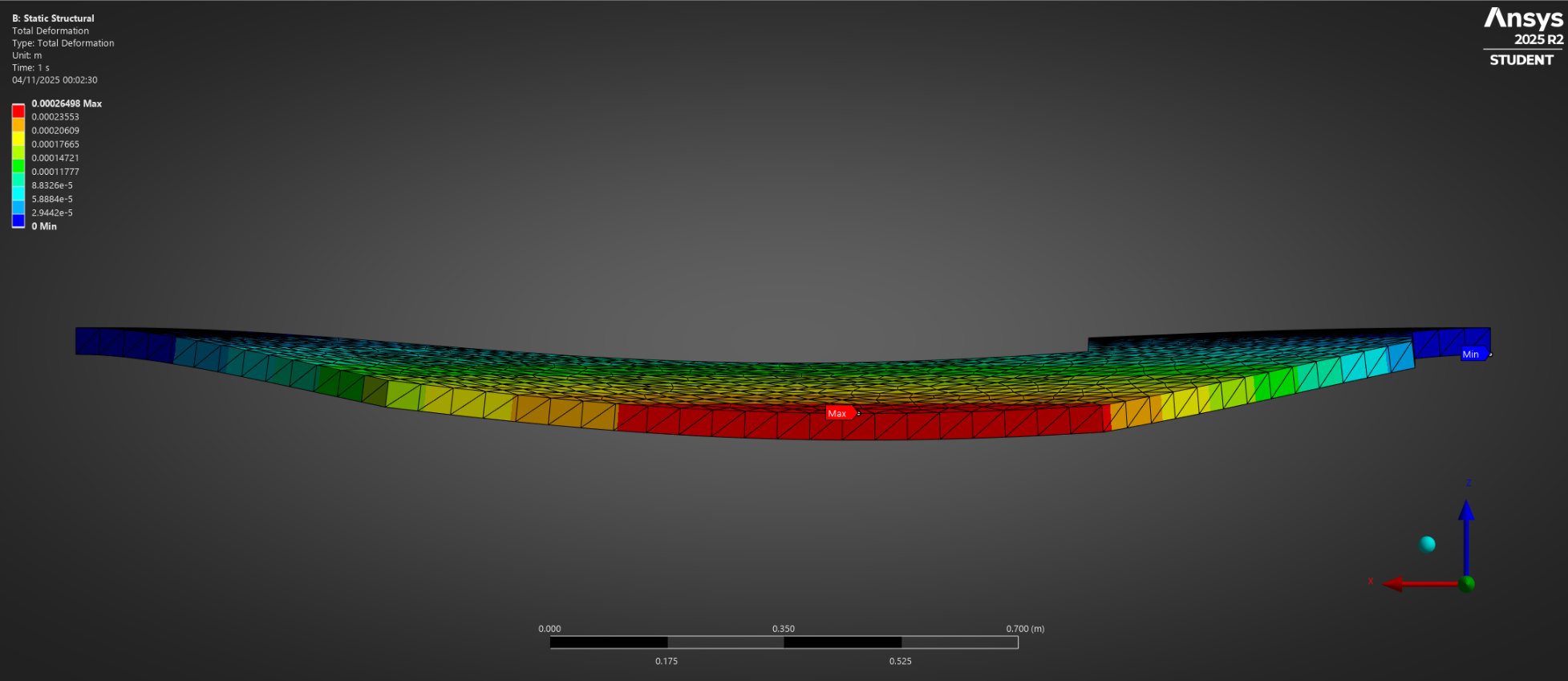

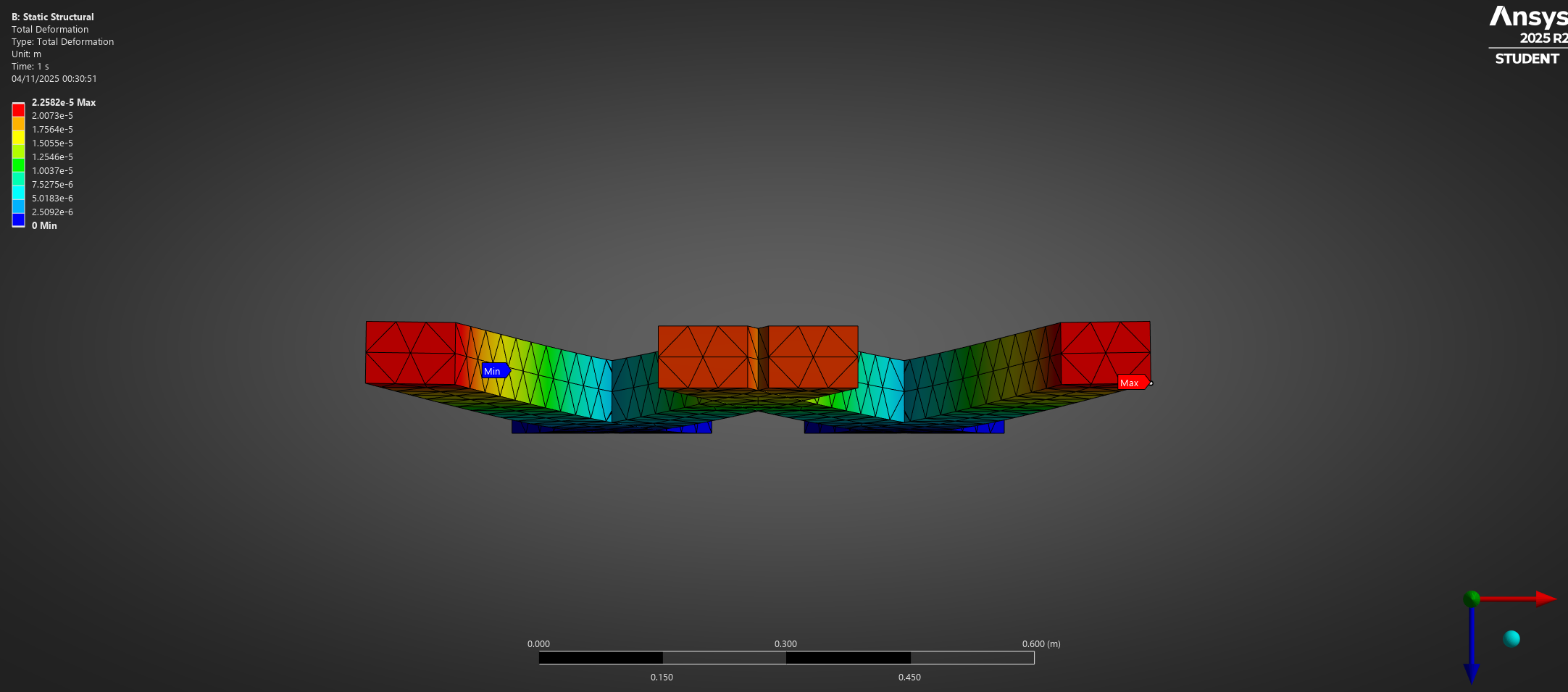

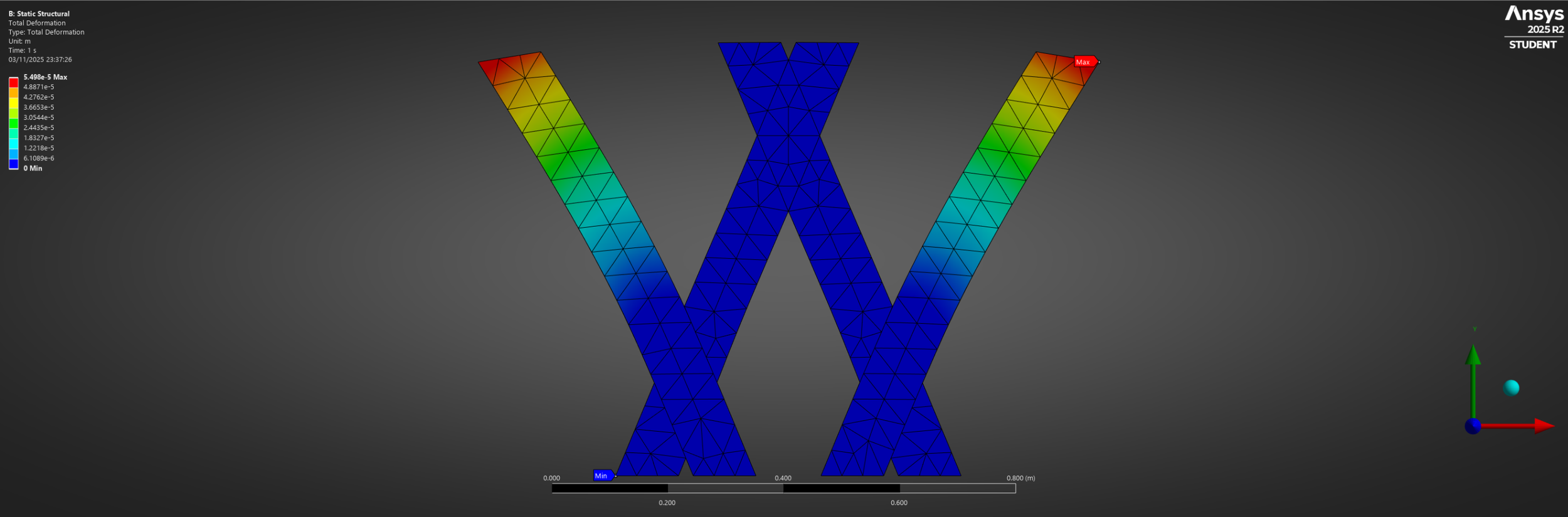

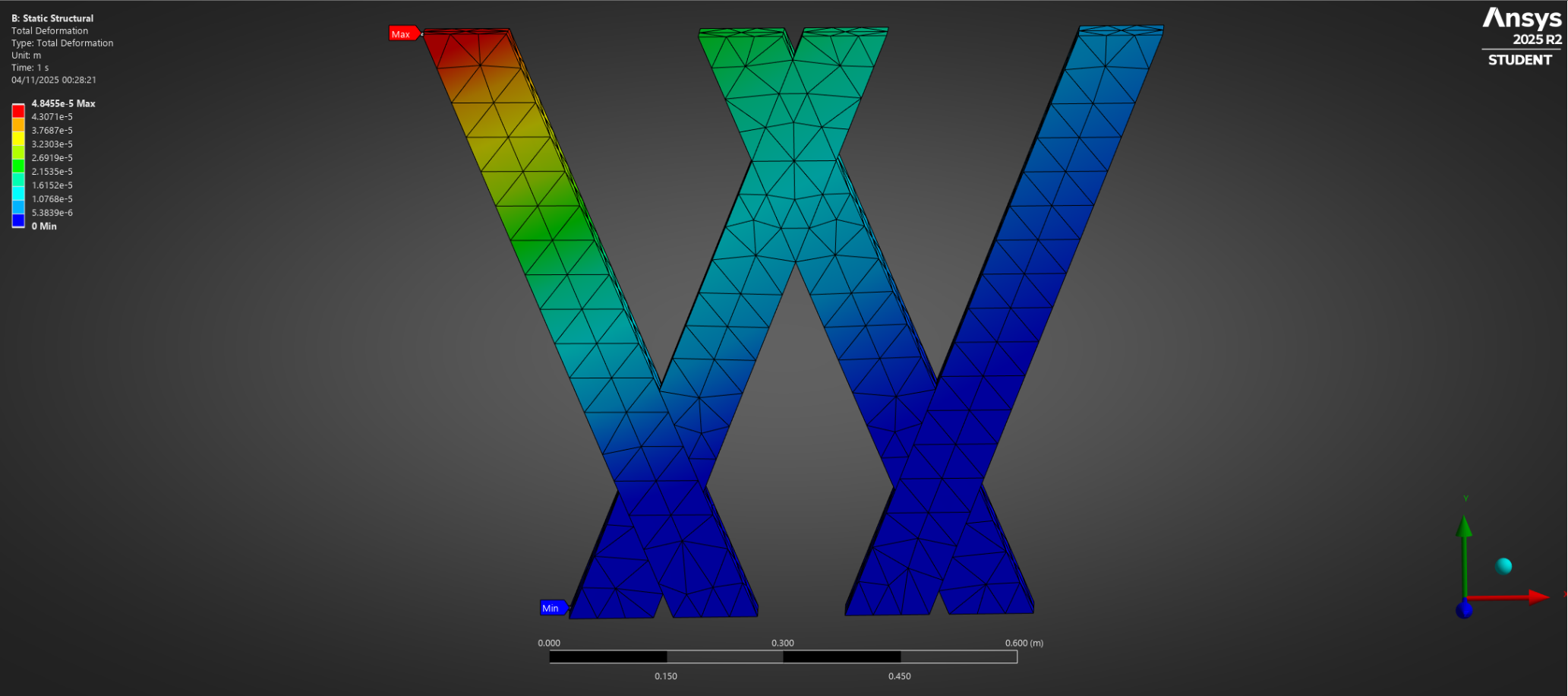

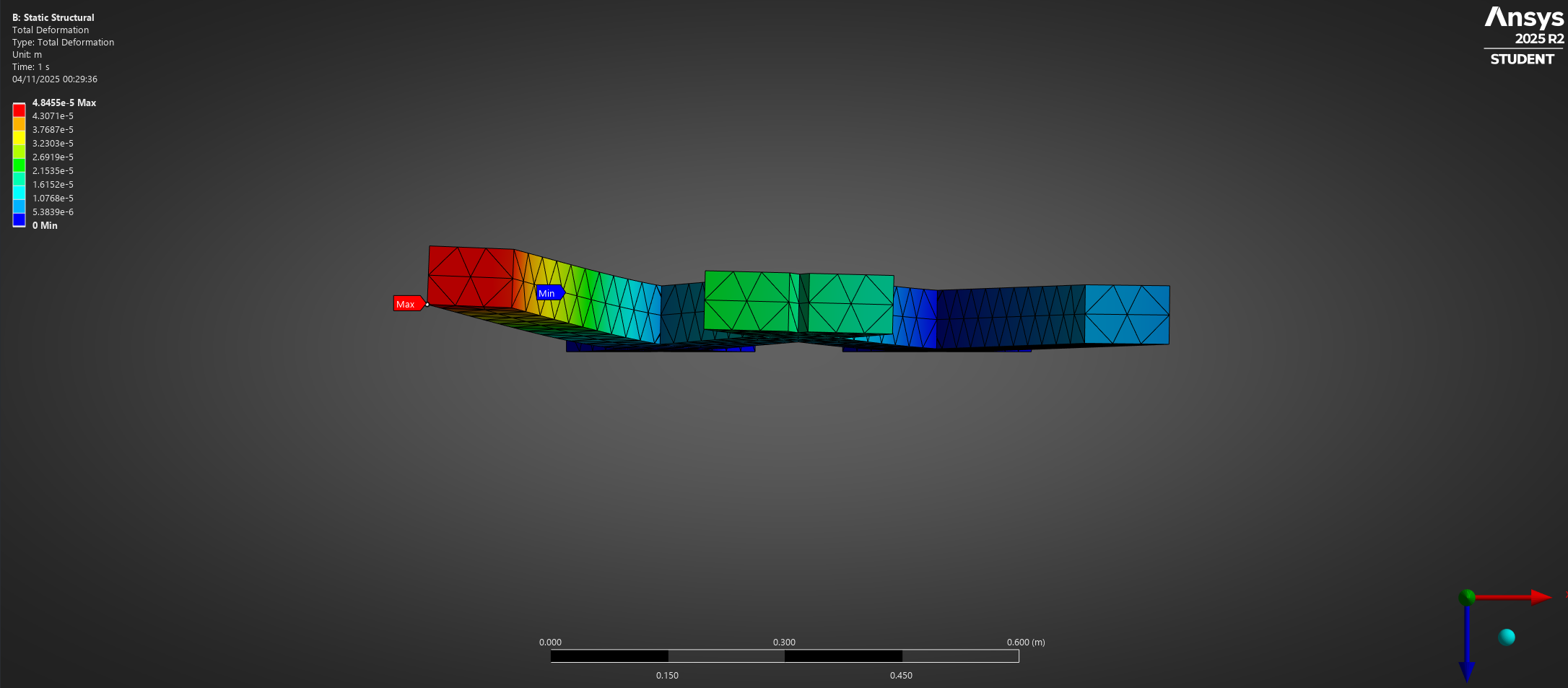

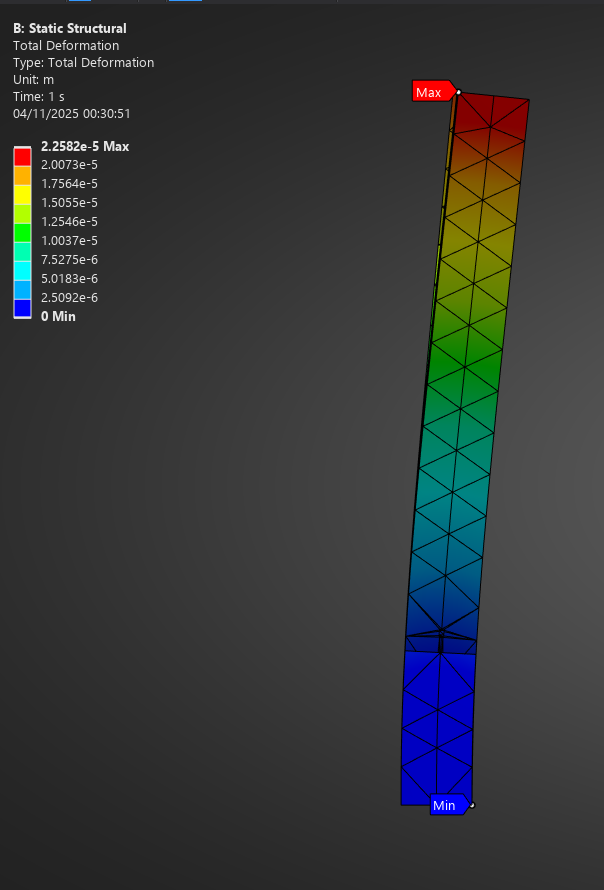

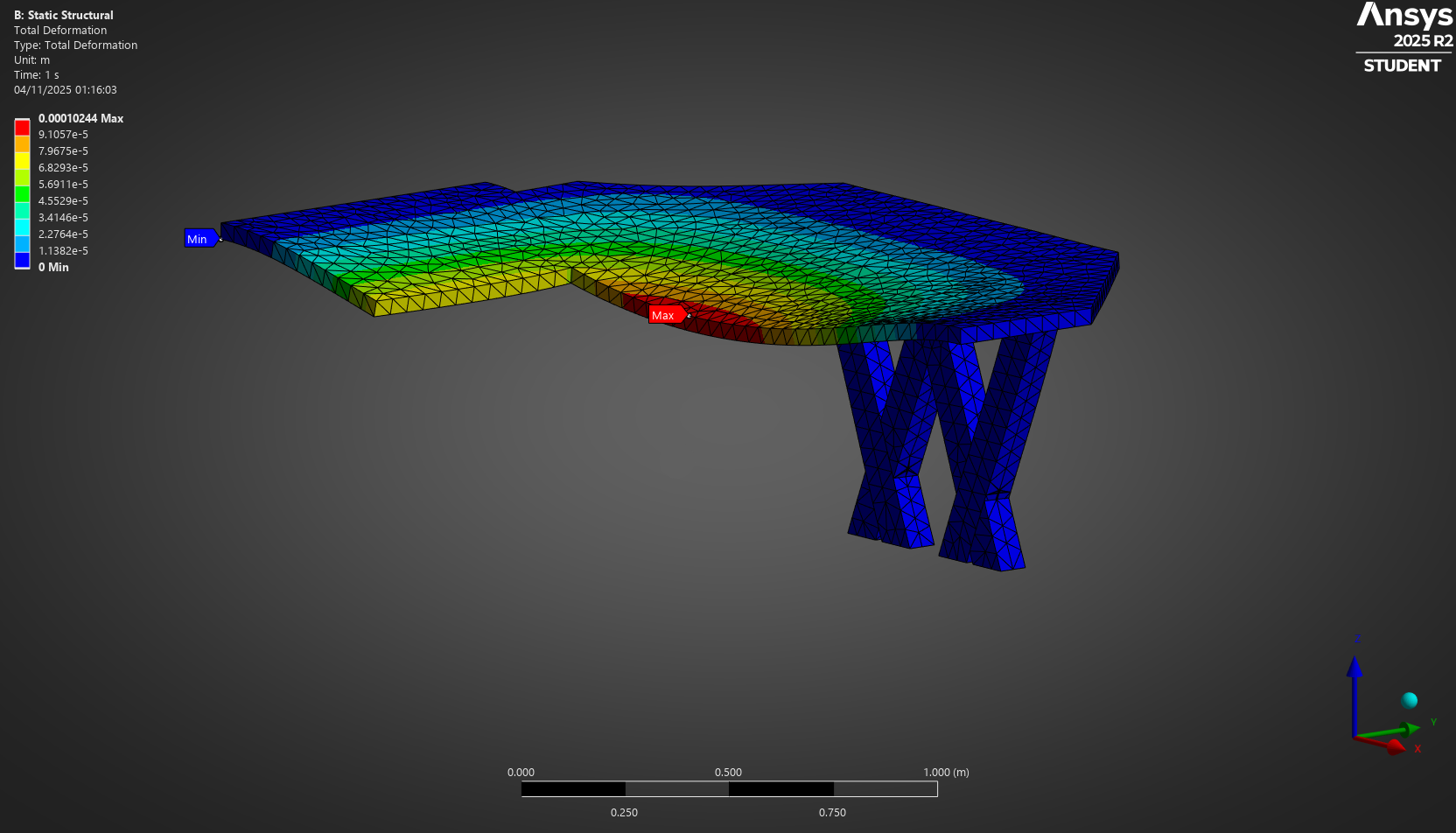

FEA simulations were conducted in Autodesk Fusion 360 and ANSYS to evaluate deformation under realistic loading conditions — a key factor guiding the desk’s structural design. The analysis was divided into three stages: first, the legs were isolated to assess deformation under the desktop’s weight; second, the desktop was analysed independently to identify critical support regions; and finally, the full assembly was tested to simulate real-world use.

Fixed supports were applied where the legs contact the floor and along the desktop’s wall-mounted edges. A total load of 450 N was applied to represent the desk’s weight and additional usage loads. Results confirmed excellent stiffness and stability, validating the design before fabrication and informing minor optimisations to further enhance rigidity and performance.

Iteration

To address issues identified during the simulation phase, I introduced reinforcement brackets to improve the connection between the desktop and leg assemblies. These brackets were chosen to prevent structural instability in the event of accidental lateral movement or impact on the legs. Beyond strengthening the overall frame, the modification also provided additional support for the desktop, enhancing rigidity and extending the desk’s long-term durability. This iterative refinement ensured the final design maintained both its structural integrity and clean aesthetic.

Desk Legs Before Simulation

Desk Legs After Simulation

Concept Oak Desk

Final Oak Desk

Final CAD Model + Technical Drawings

Following the iterations described above, the project has reached the pre-manufacturing phase, where an instruction manual is required to ensure accurate fabrication of the legs and desktop. To support this, a set of detailed technical drawings has been produced, outlining precise dimensions, tolerances, and assembly guidance for the manufacturing process.

Manufacturing

The manufacturing process for the desk presented several challenges and inefficiencies, primarily because the project took place alongside a full home renovation that I was also undertaking. Additionally, limited workspace meant that materials could not all be purchased or stored simultaneously, requiring a staged approach to fabrication. Despite these constraints, the process provided valuable hands-on experience in planning, sequencing, and adapting to real-world conditions.

Over the span of two weeks, a 5-metre-long hardwood beam was transformed into a set of cross-braced legs, designed for optimal rigidity and aesthetic balance. Each leg component was measured, cut, and assembled using precision joinery techniques before being sanded, primed, and painted to a high-quality finish. The desktop was fabricated in parallel, including planing, edge preparation, and the application of a protective surface coating to enhance durability and highlight the natural grain of the timber.

The final assembly combined craftsmanship with engineering precision — ensuring that both the visual quality and structural integrity of the desk reflected the design intent established during the simulation and modelling stages.

Final Thoughts

In summary, I am proud to have taken this project from an initial concept through to a fully realised, physical product — created entirely by hand. The experience was not only technically rewarding but personally fulfilling, as it demonstrated the value of persistence, adaptability, and problem-solving in the face of both expected and unforeseen challenges.

This project will always serve as a reminder that with curiosity, commitment, and the willingness to learn through every stage of the process, it is possible to transform an idea into something tangible and meaningful.