Reusable Takeaway container

A sustainable and innovative approach to tackling the environmental impact of single-use takeaway packaging.

The project followed a structured, three-phase design process — from research and decision-making to testing and system implementation — integrating sustainability, aesthetics, and user experience.

Phase 1

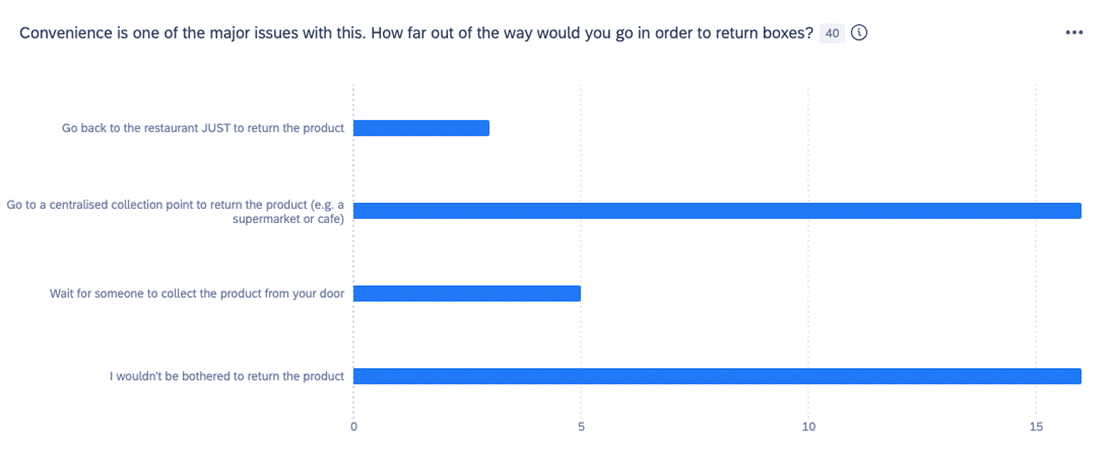

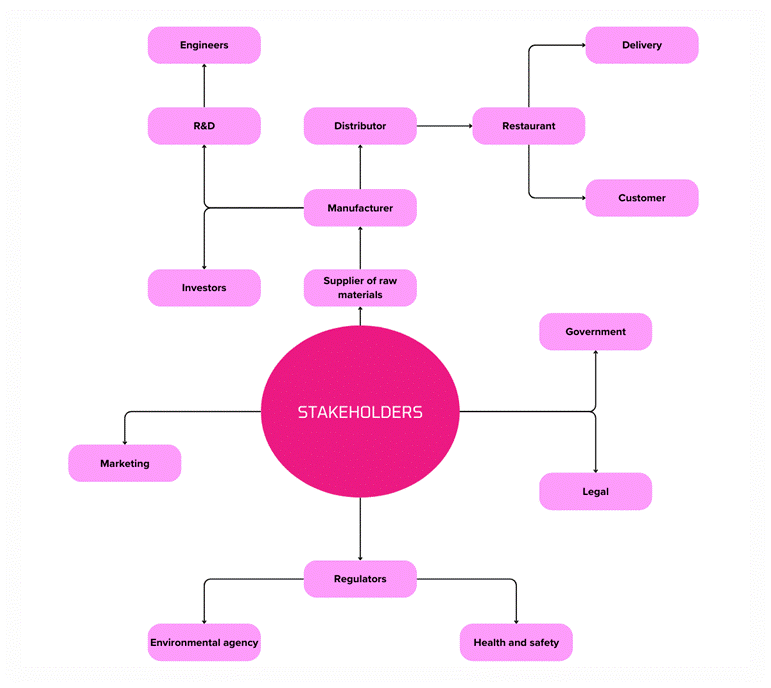

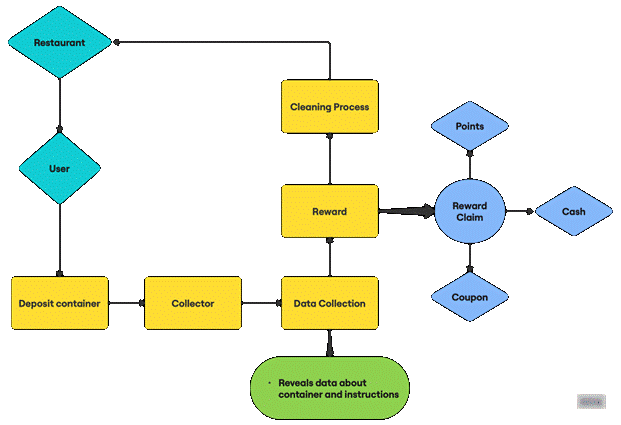

The project began with an in-depth exploration of the takeaway packaging market, identifying issues with current single-use systems and understanding the needs of key stakeholders — customers, restaurants, and manufacturers.

This phase involved extensive research, analysis, and decision-making, including:

Conducting market and stakeholder research to define the problem space.

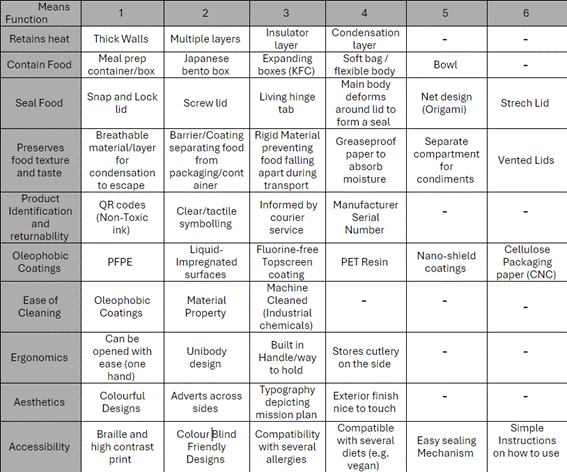

Creating decision matrices and morphological analyses to compare design directions.

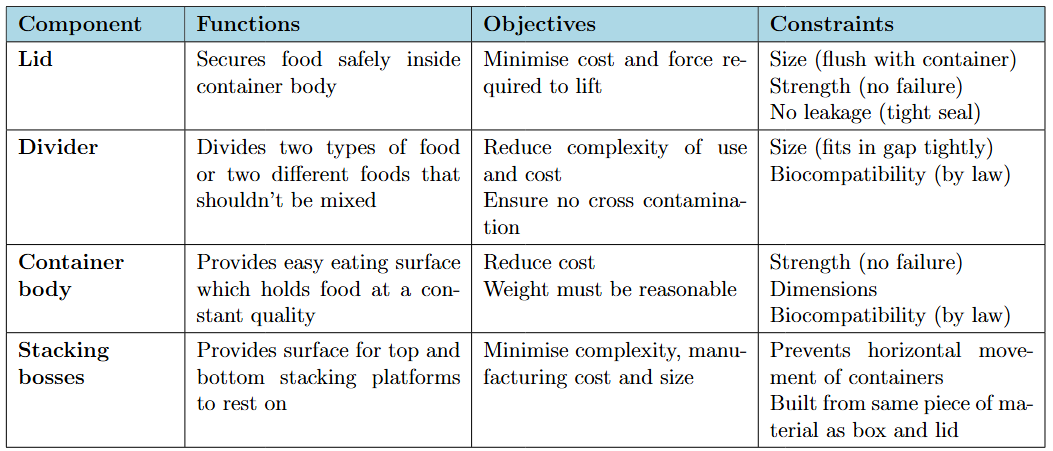

Establishing Functions, Objectives, and Constraints (FOCs) to guide ideation.

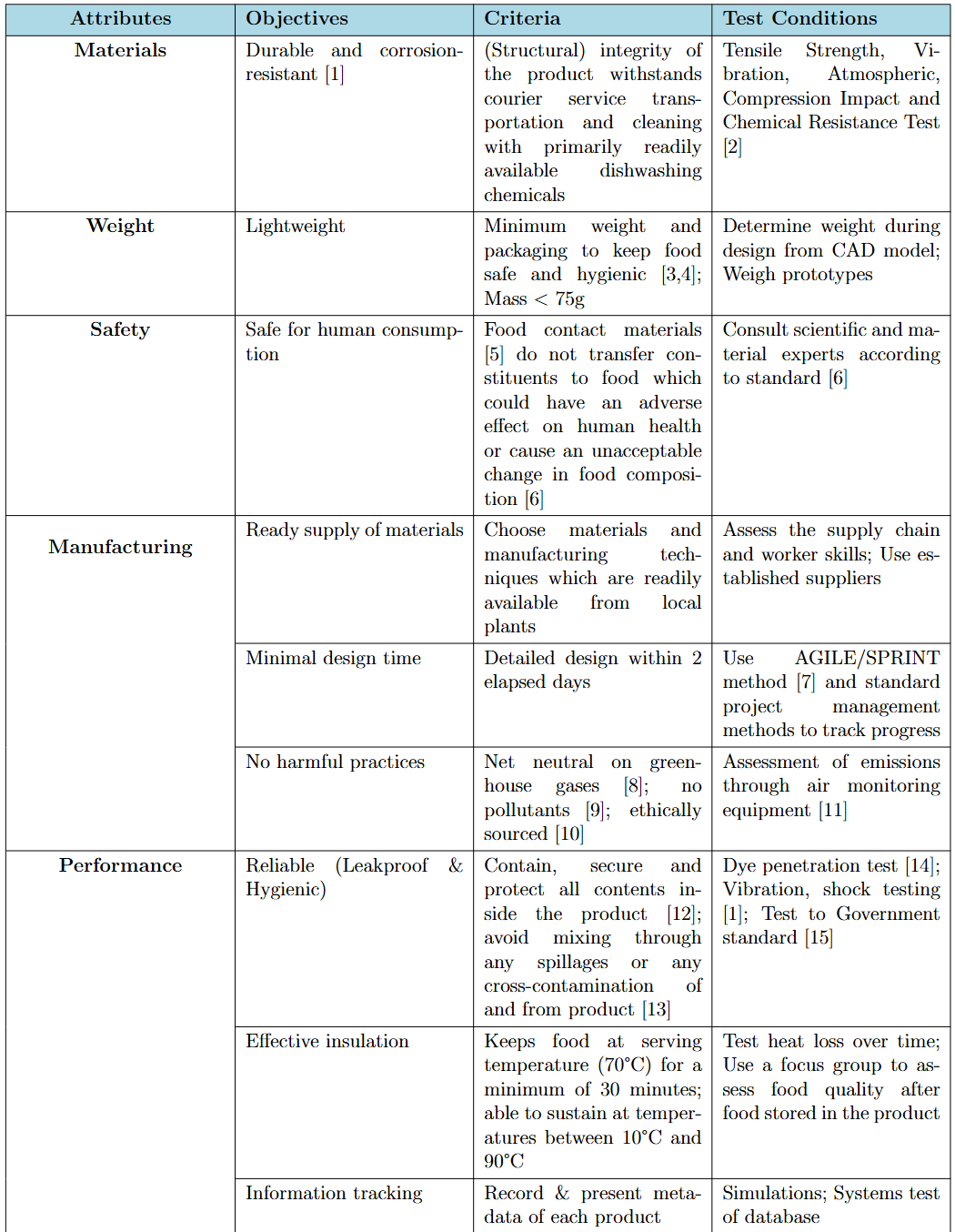

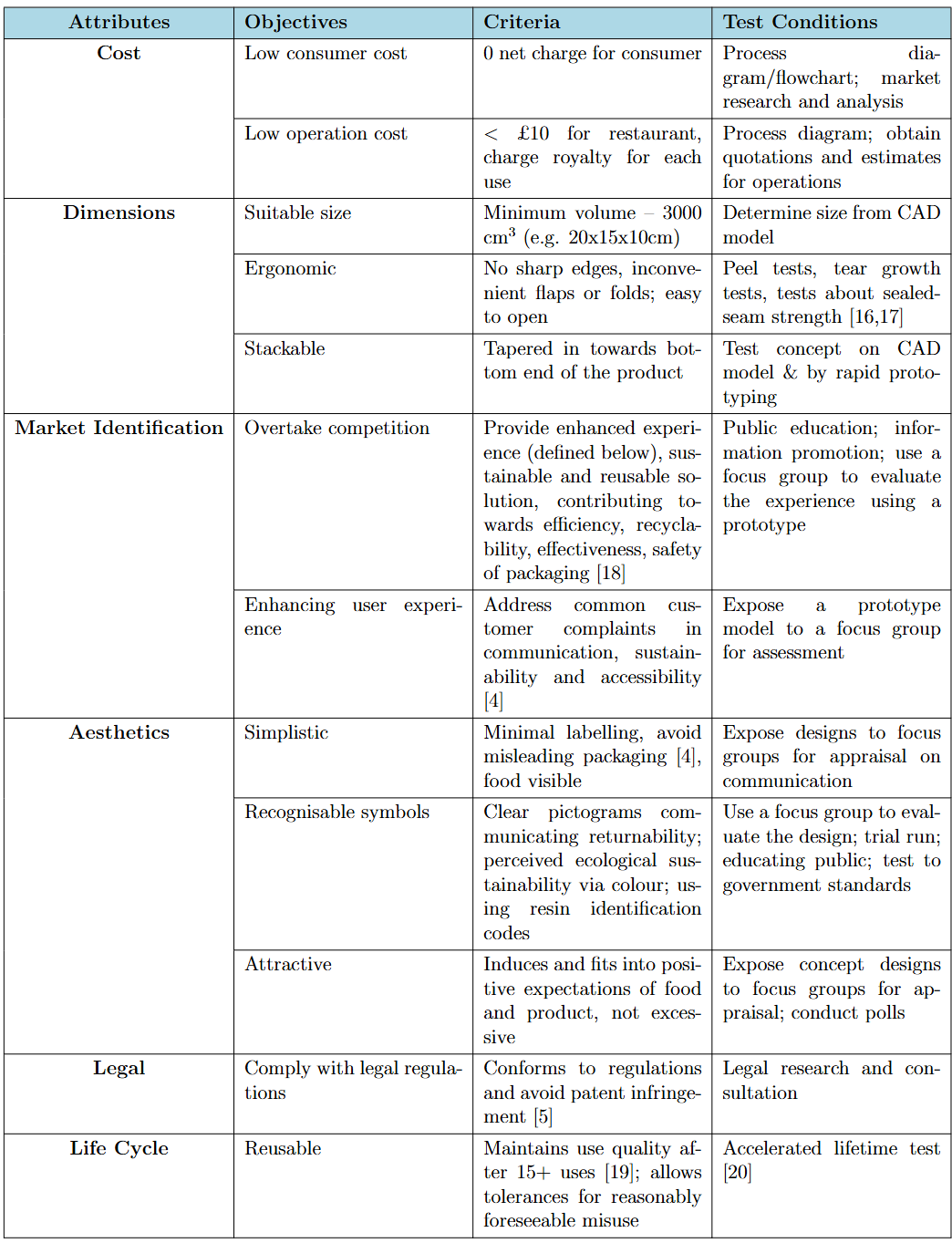

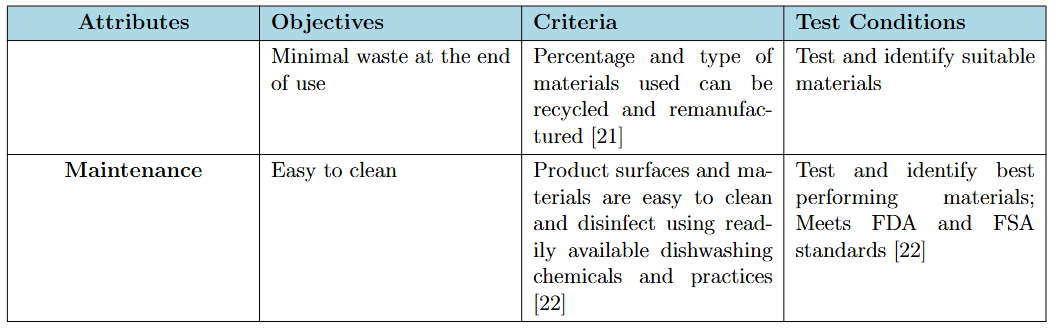

Developing a detailed Product Design Specification (PDS) outlining functional, environmental, and legal requirements, ensuring compliance with food safety and sustainability standards.

This foundational phase set the criteria for all subsequent design and engineering decisions.

Phase 2

In this stage, attention shifted to form, functionality, and manufacturability.

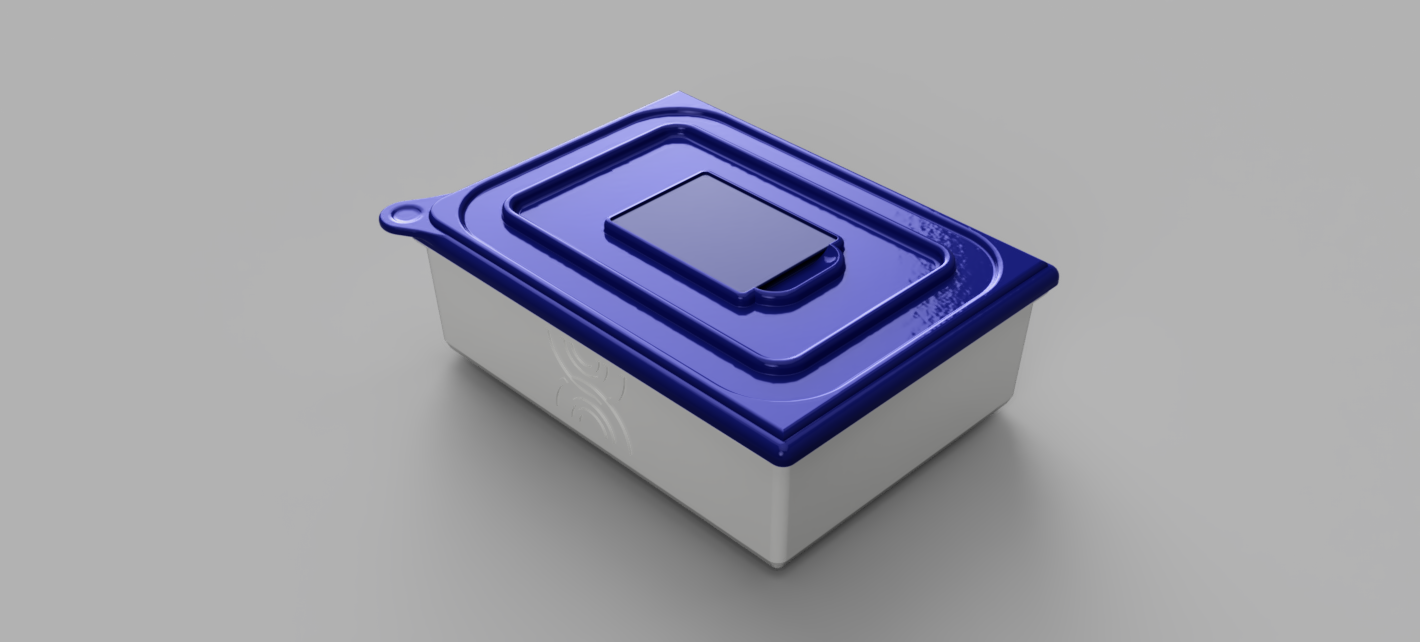

The goal was to visualise and test how the container could meet the established PDS while remaining efficient, reusable, and appealing to users.

Key steps included:

Generating and refining multiple design concepts through sketching and evaluation.

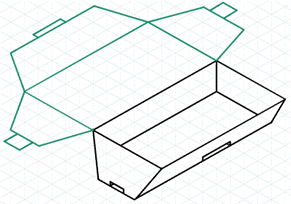

Creating rapid cardboard prototypes to test ergonomics, lid mechanisms, and volume capacity.

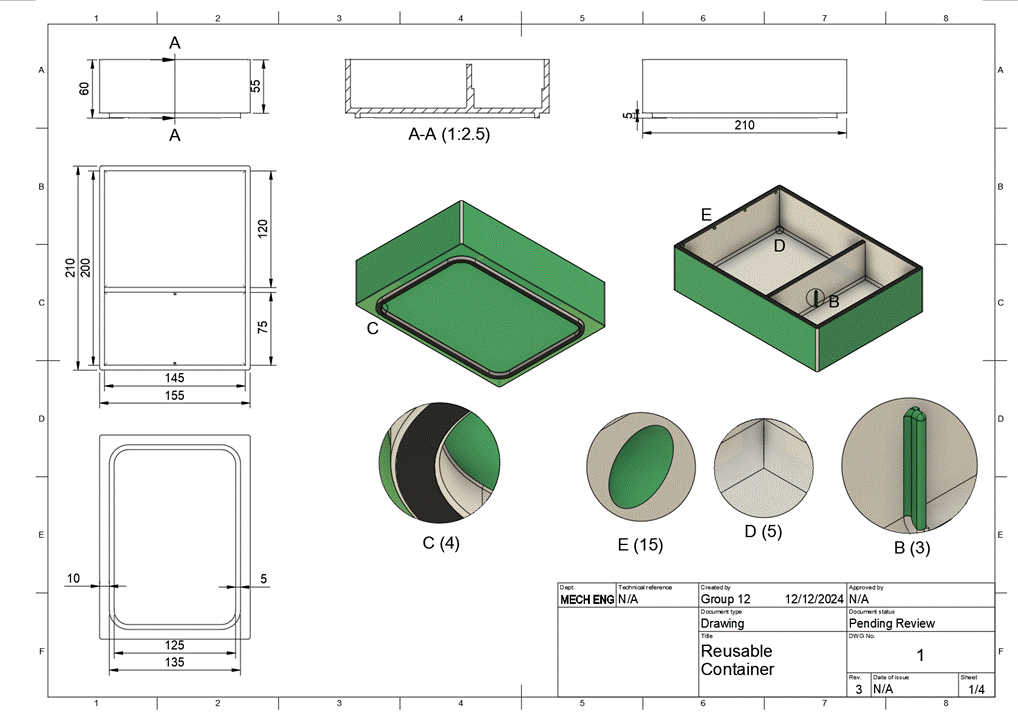

Producing 3D CAD models to study part geometry, sealing interfaces, and assembly methods.

This phase encouraged rapid iteration, allowing design improvements to be guided by both functional needs and user insights.

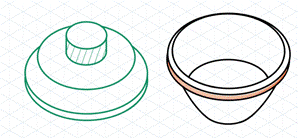

Concepts

The four concepts presented below illustrate the overarching design directions that influenced the development of my final container. Each concept also reflects the potential type of food or cuisine the container is best suited for, helping to define its intended use context and aesthetic inspiration.

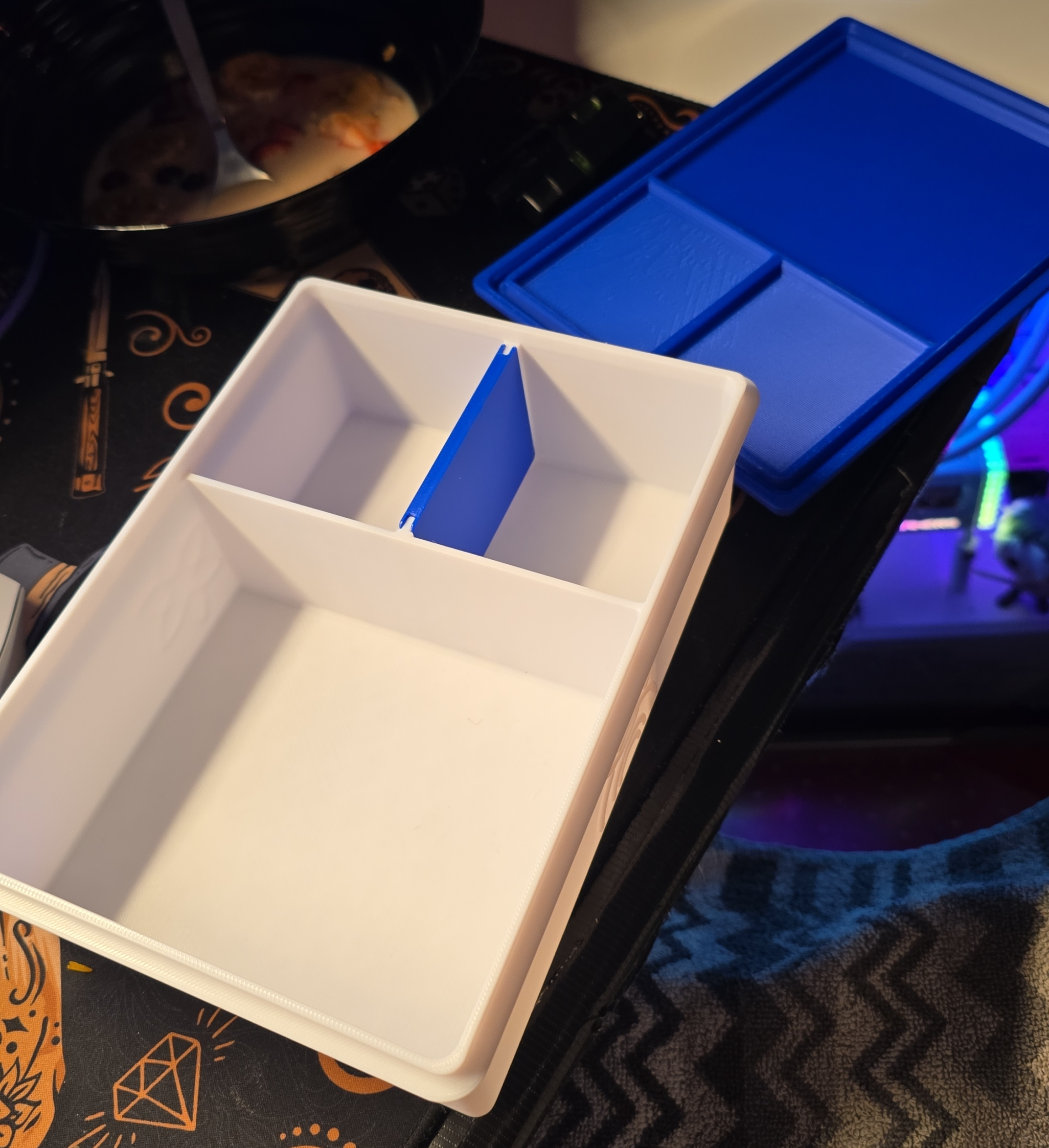

Prototyping and Design Development

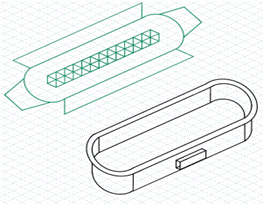

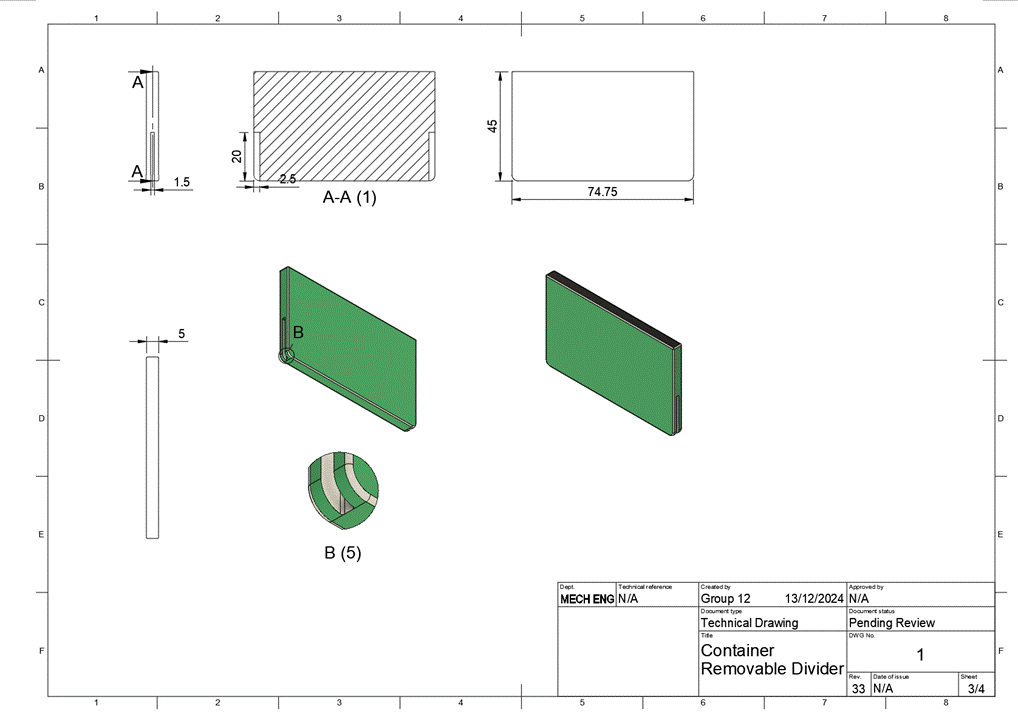

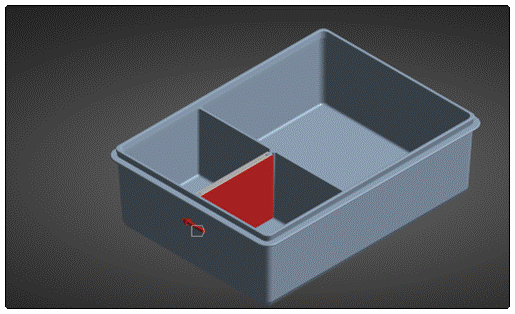

The idea of incorporating a divider was particularly appealing, as it allowed for a greater variety of dishes to be stored within the same container. The divider’s primary function was to enable separation of foods and condiments that would typically be packaged in smaller disposable tubs, integrating them directly into the reusable design.

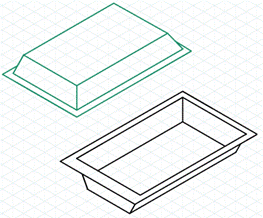

Prototype 1 focused on developing a sense of scale and assessing whether commonly ordered meals could fit comfortably within the container while maintaining a “restaurant-quality” presentation for the customer.

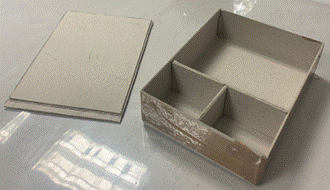

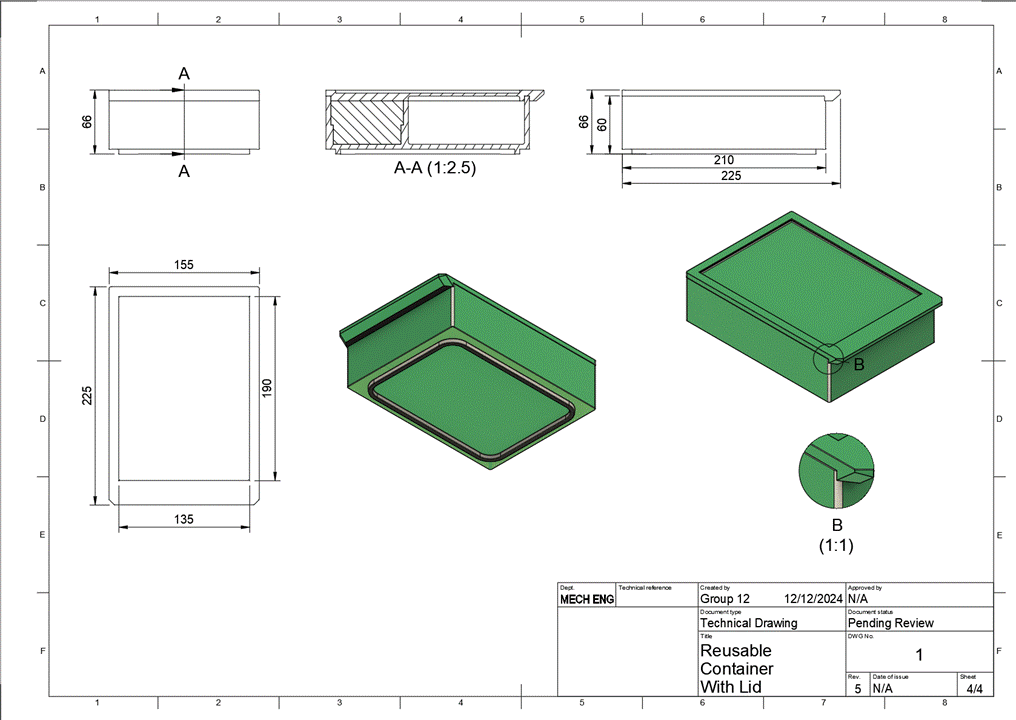

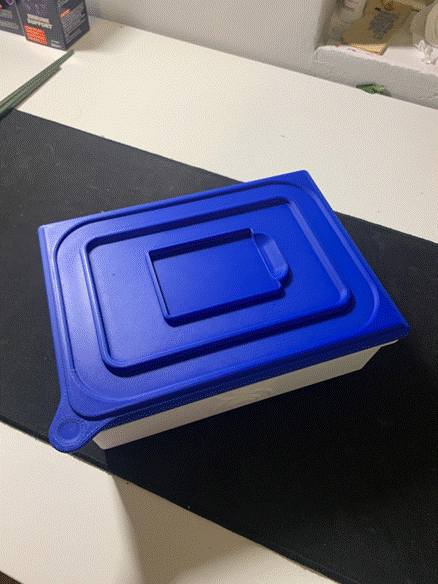

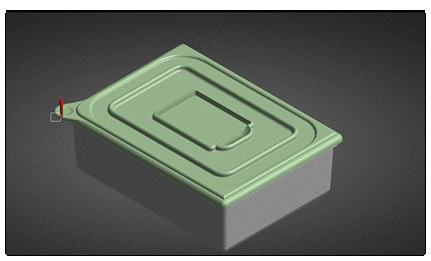

Prototype 2 introduced the container as a complete assembly, including the lid and divider. This stage revealed that the lid was overly material-dense and could benefit from weight reduction through hollowing certain regions. The extruded section on the lid was specifically designed to interlock with the divider wall and container sides, forming a tight seal that completely separated the compartments.

At this point, the divider design also evolved — now creating three distinct compartments. Unlike the first prototype, where the divider was fixed, the second iteration featured a removable small divider and a fixed long divider. This change was made after recognising that different cuisines often include dishes with varying numbers of components. While a fully removable divider offered greater flexibility, it also introduced lateral weakness and a shorter expected lifespan. Therefore, a hybrid approach was adopted: keeping the main divider fixed for structural integrity, while making the smaller divider removable to support modular use.

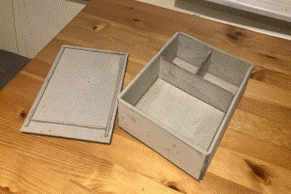

Prototype 3 implemented this final configuration and was presented to a panel of engineers, whose feedback informed the next phase of refinement and testing.

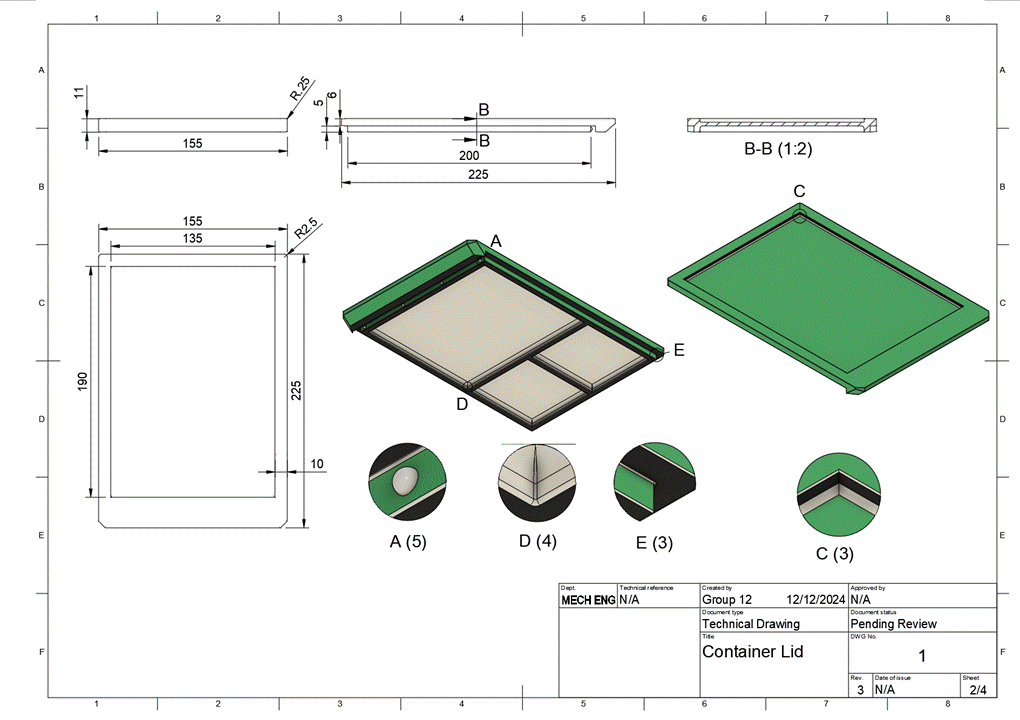

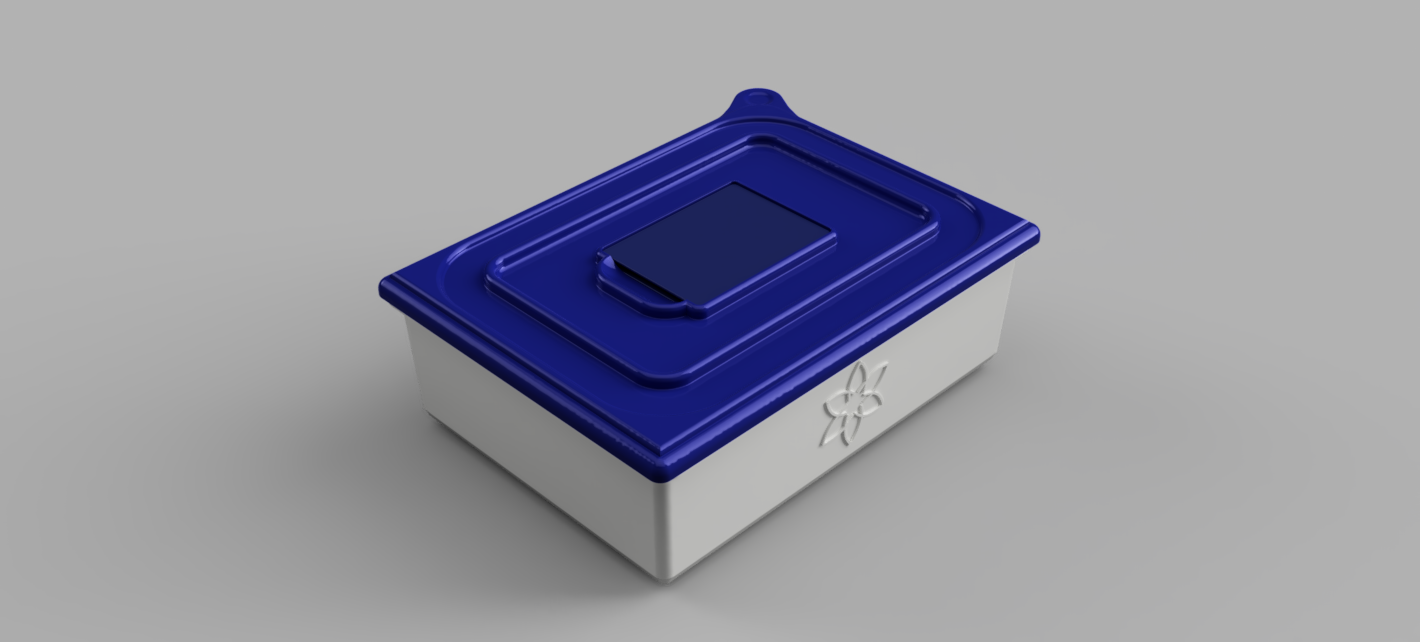

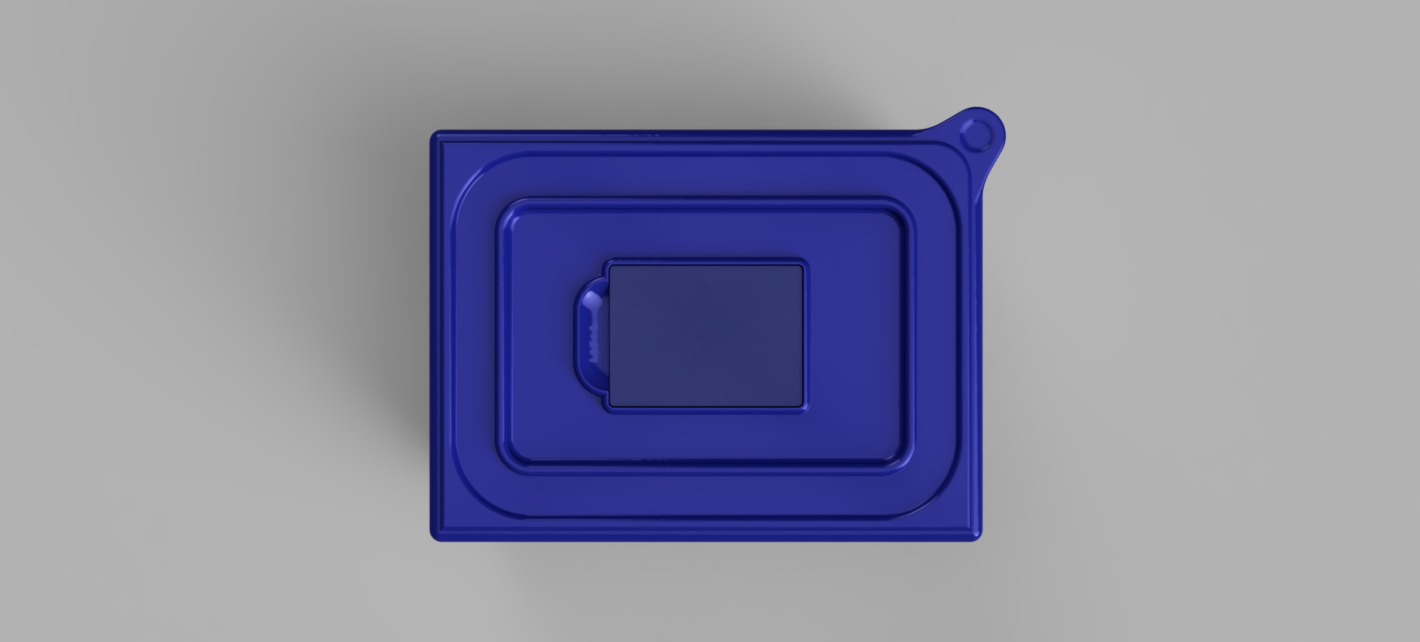

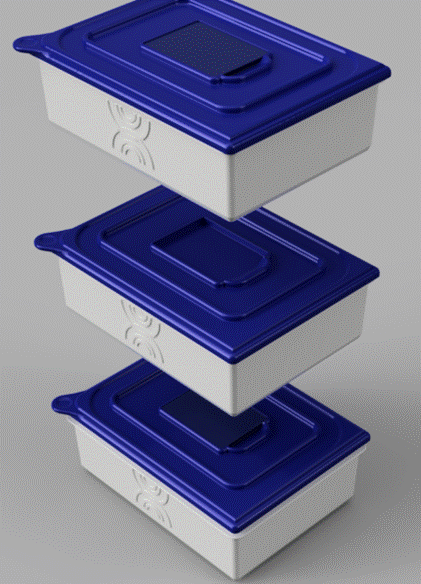

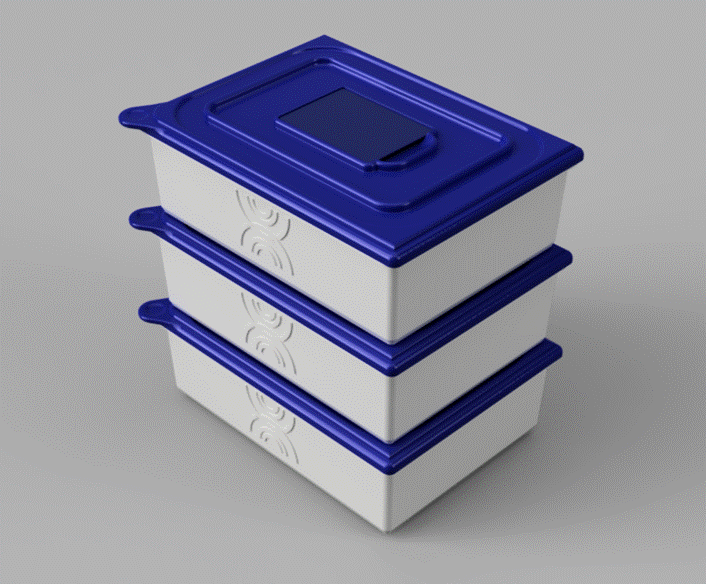

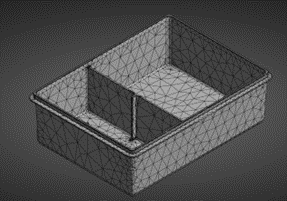

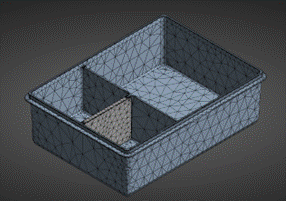

CAD

To ensure the desired container dimensions were accurately achieved, a highly precise CAD model was developed. The third prototype was manufactured to closely replicate this model, allowing the review panel to clearly understand how the final product would look and function in a real-world context.

Phase 3

The third phase focused on refinement and testing, incorporating feedback from a review panel and customer questionnaire to improve usability and overall satisfaction.

Design goals evolved to include stronger aesthetic appeal and a “restaurant-quality experience at home.”

The final design was 3D printed for evaluation but engineered for injection moulding in large-scale production.

To ensure product reliability and performance:

Thermal simulations were performed in Fusion 360, supported by real-world heat dissipation tests to maintain food quality.

Tensile and bending tests were carried out on physical specimens to evaluate mechanical strength.

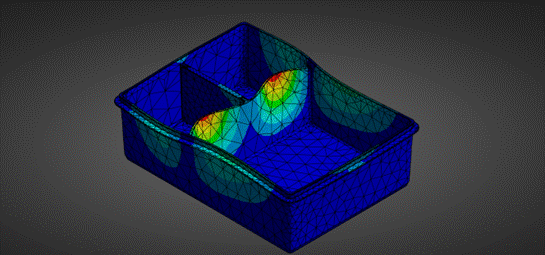

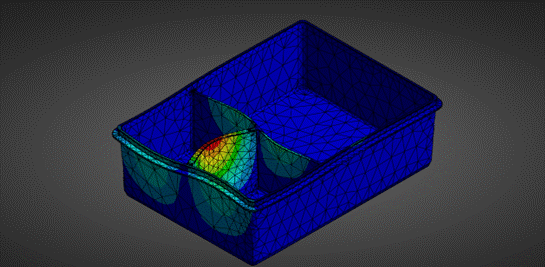

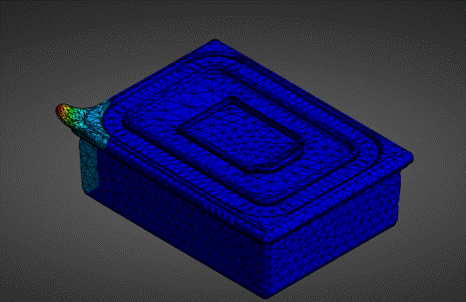

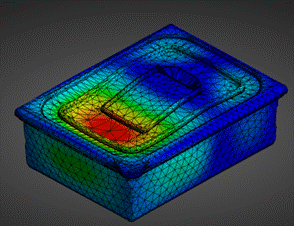

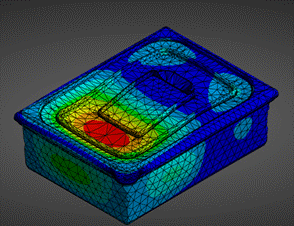

Comprehensive FEA testing in ANSYS analysed the structural performance under various loads, ensuring durability over repeated use.

This phase validated the product’s functionality, confirming that it met both sustainability and engineering performance targets.

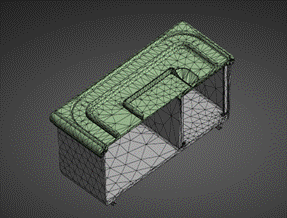

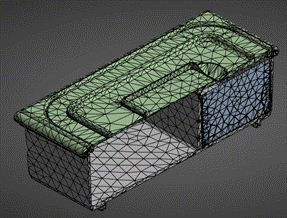

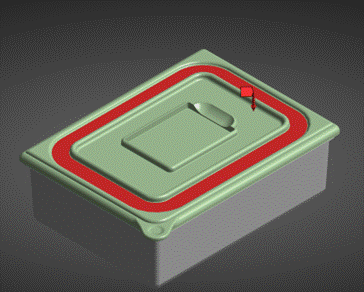

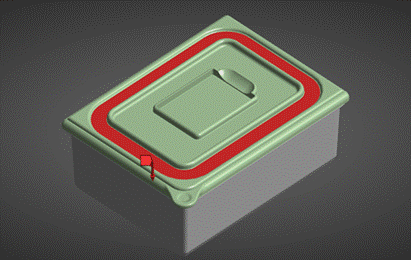

Box Mesh

Box + Divider Mesh

Box + Lid Mesh

Box + Divider + Lid Mesh

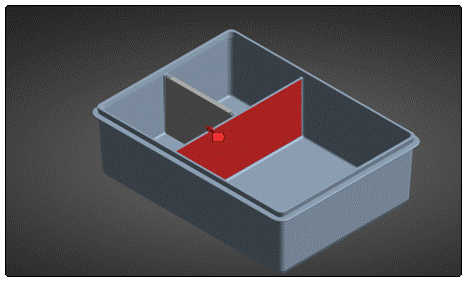

Box + Divider Fixed Divider Force Location

Box + Divider Fixed Divider Force Deformation

Box + Divider Free Divider Force Location

Box + Divider Free Divider Force Deformation

Box + Lid Tab Force Location

Box + Lid Tab Force Deformation

Box + Lid Lid Force Location

Box + Lid Lid Force Deformation

Box + Divider + Lid Lid Force Location

Box + Divider + Lid Lid Force Deformation

Material

The simulations were conducted using polypropylene (PP), the material selected after extensive research and comparison with alternative thermoplastics. Polypropylene was chosen due to its excellent balance of strength, flexibility, and chemical resistance, making it well-suited for repeated use and exposure to varying temperatures during food storage. Its low density contributes to a lightweight design, while its high fatigue resistance ensures the container can withstand the mechanical stresses of daily handling, stacking, and cleaning cycles.

From an environmental perspective, polypropylene is readily recyclable and widely available, aligning with the project’s sustainability objectives. Furthermore, its food-grade safety compliance and resistance to common dishwashing chemicals make it ideal for applications requiring both hygiene and durability. By basing the simulations on polypropylene, the analysis closely represented the real-world performance of the final product, ensuring that the design met both functional and environmental criteria.

Manufacturing

Ideal Manufacturing Method: Injection Moulding

Injection moulding was selected as the ideal manufacturing process for the container due to three main advantages:

Cost-effectiveness for large-scale production

Precision and consistency in forming complex geometries

Material compatibility with polypropylene (PP)

This process allows for high repeatability and excellent surface finish while maintaining tight dimensional tolerances. Based on estimates from Europlas, the cost per unit would be approximately £0.66, assuming a large batch production of around 10,000 units.

Prototype Manufacturing Method: 3D Printing (FDM)

For the physical prototype, 3D printing using PLA (Polylactic Acid) was employed to accurately replicate the CAD model. This method enabled the creation of a visually and dimensionally precise prototype, allowing for effective communication of the product’s design intent. PLA was chosen because it shares similar mechanical and thermal properties with polypropylene, making it a suitable substitute for testing form, fit, and basic functionality. Additionally, 3D printing provided rapid, low-cost iteration capability—ideal for showcasing the product’s features prior to full-scale manufacturing.

Final Thoughts

The ANSYS deformation studies provided valuable insight into how the container responds to forces acting on its core components and helped identify potential areas of structural weakness that could lead to failure. These results guided targeted refinements to improve strength, durability, and overall reliability of the design.

This project demonstrated the importance of combining analytical simulation with practical prototyping to create a product that is both functional and sustainable. From concept generation to CAD modelling, testing, and user validation, each stage contributed to refining a container that meets its intended purpose — offering a reusable, environmentally conscious, and user-friendly alternative to single-use packaging.